Your cart is currently empty!

About Us

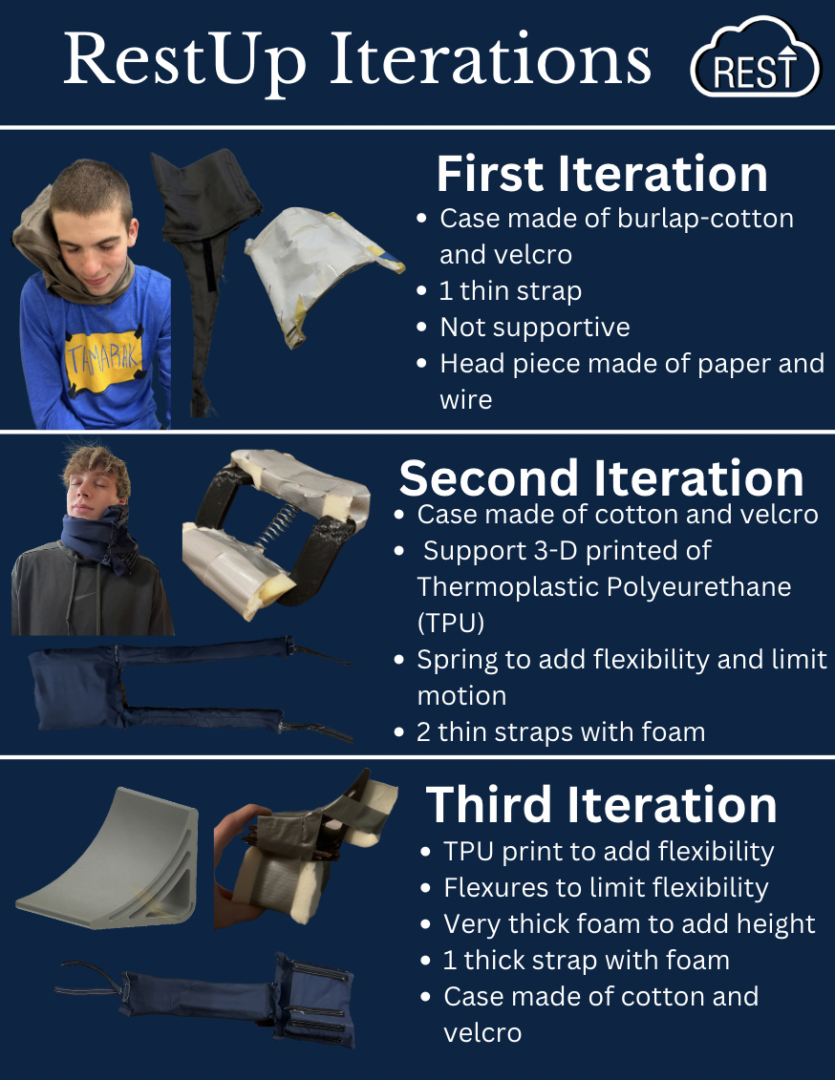

Frustrated by the limitations of traditional U-shape neck pillows, the RestUp team set out to redefine traditional travel ergonomics. Starting with simple sketches, we spent over a year refining our design, going through six iterations. Each step involved careful engineering, collaboration with manufacturers nationally and internationally, and feedback from hundreds of potential customers. Through hard work and ingenuity, we’re proud to offer a final product that provides 360-degree support and ensures proper spinal alignment for all travelers. Here’s a look at how we achieved it.

Meet Our Team

Our innovative trio of students brings fresh perspectives to travel comfort, from ergonomic design to cutting-edge manufacturing methods.

Liam Cooper

Founder, Design Manager, Manufacturing Coordinator, and Logistics Specialist

Deerfield High School Valedictorian and incoming freshman at University of Texas at Austin studying mechanical engineering with a minor in sustainable energy.

Max Feinberg

Founder, Financial Coordinator and Marketing Investor Specialist

Rising senior at Deerfield High School with an interest in FinTech–the intersection of finance and technology.

James Xiao

Product Design Lead and Engineering Graphics Specialist

Incoming freshman at Cornell University studying mechanical engineering with a minor in computer science.

Engineering/Designing

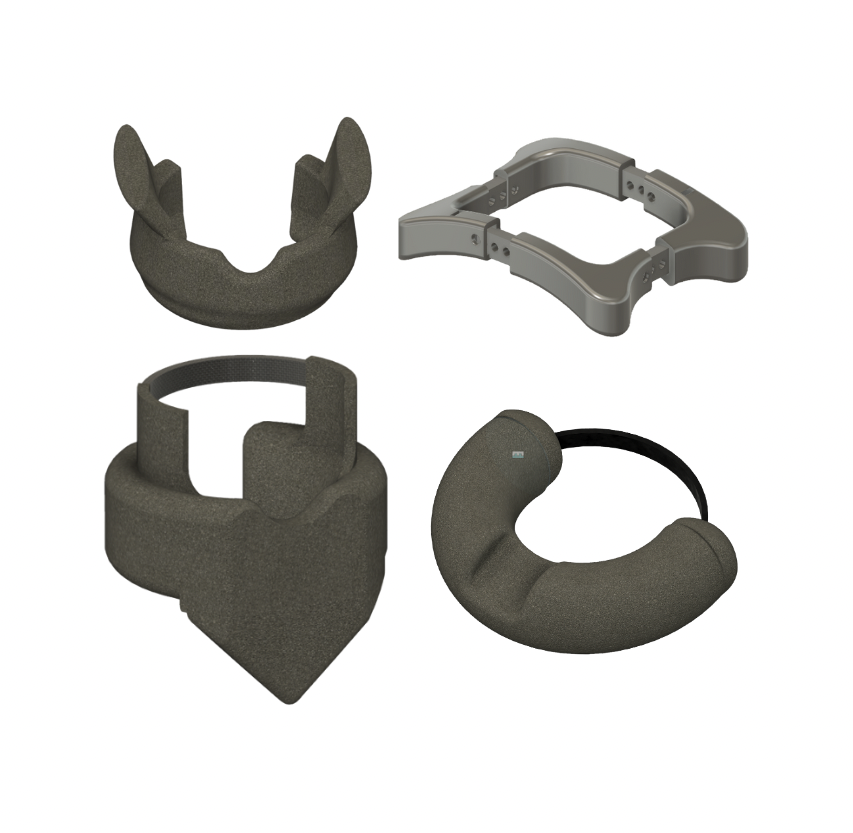

Using CAD and Fusion, we brought our ideas to life. Every adjustment made from the first iteration to the final design was guided not by our personal preferences, but by feedback from real travelers.

Manufacturing

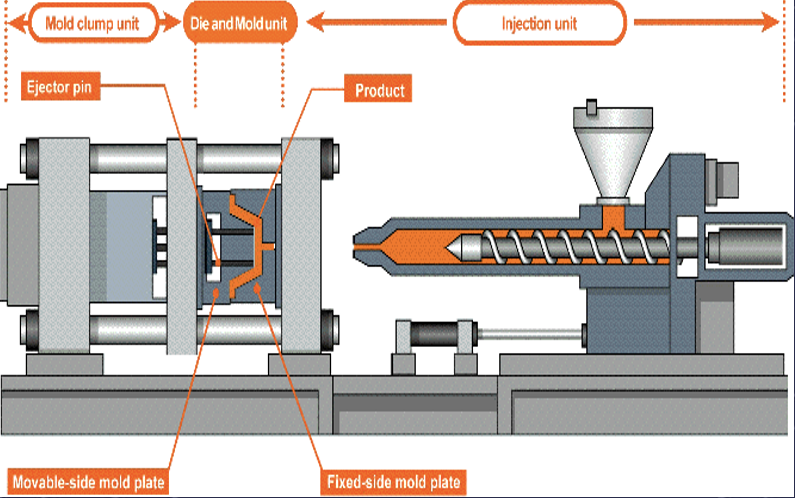

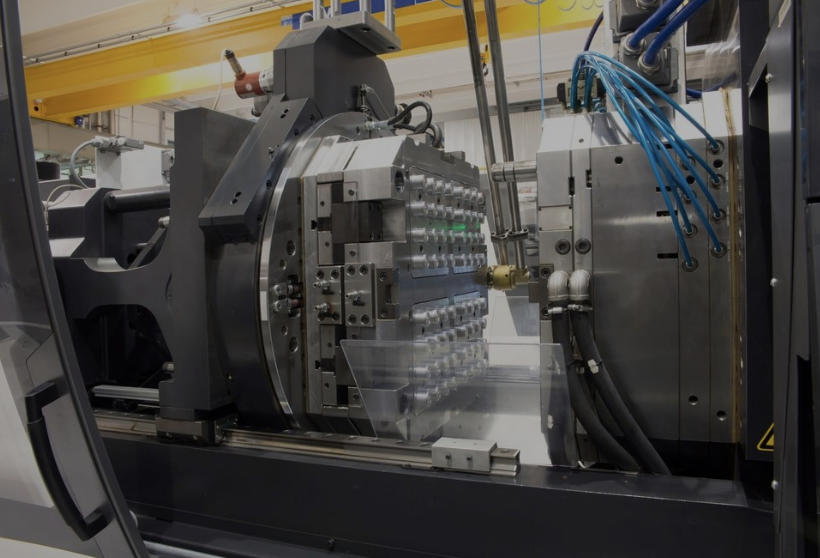

The latest RestUp Pillow model features thermoplastic polyurethane (TPU), veltex fabric, and viscoelastic foam. In partnership with Richard Wadiri, a supply chain expert with over 25 years of experience in U.S.-China production management, we source materials both domestically and internationally to ensure the highest quality and durability. Below, we highlight the manufacturers we collaborate with and provide insights into the pillow-making process. The next phase of production will include injection molding to further enhance the manufacturing process.

Funding

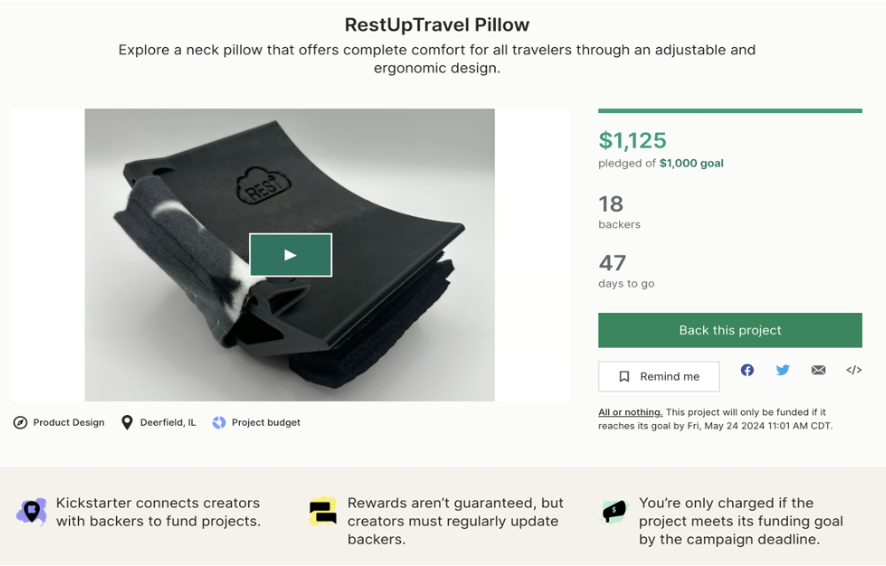

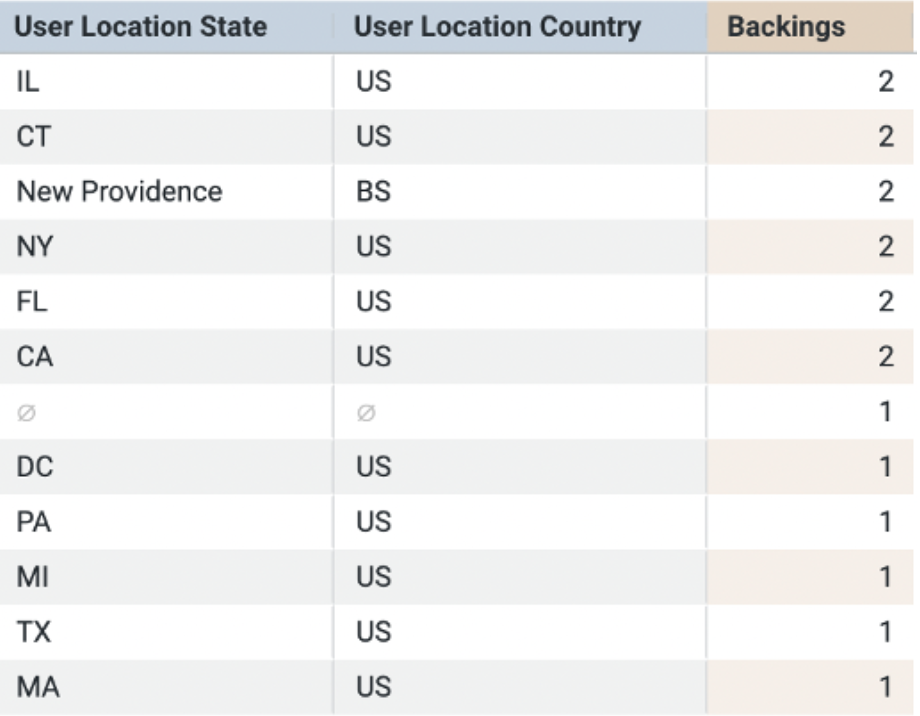

As students, funding a start-up with a $0 budget is incredibly challenging. Building the product outside of school would have been impossible without some initial capital. To overcome this, we launched a 60-day, all-or-nothing campaign on Kickstarter to raise funds. By connecting with 20 investors both nationally and internationally, we successfully raised over $1,000, allowing us to launch our first short-run production. https://www.kickstarter.com/projects/restuptravel/restuptravel-pillow?ref=nav_search&result=project&term=restuptravel&total_hits=1

Selling/Trade Shows

With funding secured, we were ready to start selling. We began by pitching our product at in-person trade shows, where we could engage directly with customers and experience making our first sales. The response was overwhelmingly positive, with many attendees pledging their support and showing great interest in our product. Some even shared that it was the best travel pillow they had ever used.